How Will qhpreformmould Bottle Blowing Mould Supplier Support Flexible Manufacturing Needs

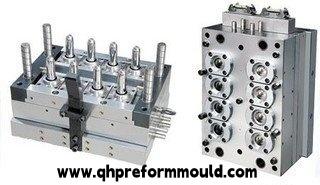

For manufacturers seeking efficient and adaptable solutions, selecting the right Qihong Bottle Blowing Mould Supplier can significantly impact operations. Quality moulds influence productivity, material use, and operational cost. qhpreformmould provides moulds designed for durability, practical usability, and consistent shaping, helping facilities maintain smooth workflows and reduce waste. By choosing a supplier that balances performance with operational convenience, businesses gain predictable results and smoother production cycles.

Efficiency begins with consistent cavity formation. Moulds must produce bottles with uniform wall thickness, accurate neck alignment, and even surface quality. When each container meets specifications, downstream processes such as filling, labeling, and packaging proceed without interruption. Facilities using qhpreformmould can maintain steady output while minimizing labor input, ensuring that operators can focus on workflow management and quality control rather than constant adjustments.

Maintenance convenience is equally important for operational success. Moulds designed for easy cleaning, clear cavity access, and ergonomic handling allow operators to perform inspections and minor adjustments without halting production. Reduced downtime enhances workflow stability, lowers labor intensity, and improves staff efficiency. By combining practicality and durability, qhpreformmould moulds make operations more manageable and predictable.

Flexibility in production is another advantage when working with adaptable moulds. Manufacturers can adjust to different bottle sizes or minor design variations without changing equipment entirely. This capability allows facilities to respond efficiently to market demands and customer requests, maintaining stable output while producing multiple container types. qhpreformmould provides solutions that maintain quality consistency while supporting versatile production lines.

Cost efficiency is closely tied to productivity and material management. Precise cavity shaping reduces scrap and prevents defects, lowering operational expense. By ensuring predictable output, qhpreformmould moulds help facilities save on energy and labor while maintaining steady throughput. Investments in reliable moulds contribute to smoother operations, better resource management, and enhanced workflow efficiency.

Durability is critical for long-term operational stability. High-quality materials, reinforced surfaces, and precision engineering prevent wear and deformation during continuous use. Facilities benefit from moulds that retain cavity integrity, reduce maintenance frequency, and sustain steady production. Operators notice smoother line performance, fewer interruptions, and predictable results, enhancing both efficiency and confidence in daily operations.

Environmental and operational considerations are enhanced through efficient mould design. Smooth material flow, consistent cavity shaping, and minimized waste support more sustainable production practices. Facilities can maintain consistent output, reduce energy use, and improve overall operational efficiency while achieving high-quality results. qhpreformmould combines practicality, precision, and durability to provide moulds that meet modern manufacturing demands.

By choosing moulds from qhpreformmould, manufacturers gain solutions that balance durability, flexibility, and usability. Facilities experience predictable output, lower operational strain, and improved workflow efficiency. For businesses seeking professional bottle blowing moulds designed to support cost-effective, adaptable, and reliable production, visit Taizhou Qihong Mold Co., Ltd.:https://www.qhpreformmould.com/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness